NDT tests - methods MT+UT

MT: CAN EN ISO 17638 Non-destructive testing of welds - magnetic powder method

The magnetic powder method is one of the most widespread techniques for inspecting the surfaces of various products made of magnetic materials.

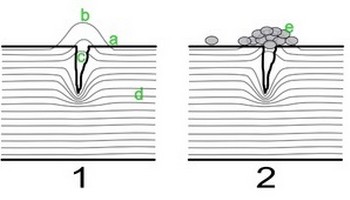

The magnetic powder test is focused on detecting material defects interacting with the surface. The magnetic powder method, similar to the penetration method, visualizes surface defects while identifying imperfections located just below the surface. The tested materials must be magnetic - ferromagnetic materials! Our trained staff deal with magnetization using a hand-held electromagnet - JHA.

Basic standards used

Magnetic tests are performed by an MT inspector, qualified according to ISO 9712, level 2:* ČSN EN ISO 23278 NDT - Testing of welds by the magnetic powder method - Degrees of acceptance* ČSN EN ISO 9943-1 Testing of materials and products by the magnetic powder method - General principles* ČSN EN ISO 9934-2 Testing of materials and products by the magnetic powder method - Test equipment* ČSN EN ISO 9934-3 Testing of materials and products by the magnetic powder method - Instruments

* We perform magnetic tests in our own and directly at customers premises’.* Evaluation of the magnetic test according to the standard ČSN EN ISO 23278; the result is recorded in the Protocol.

UT: CAN EN ISO 17640 Non-destructive testing of welds - Ultrasonic testing

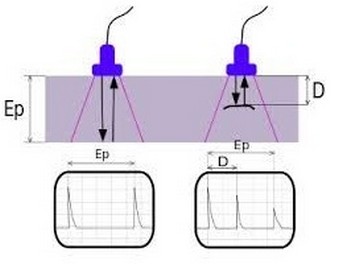

Ultrasonic testing is one of the basic methods of non-destructive material inspection. This test uses the passage of ultrasonic waves - material. The basis of most measurements is the measurement of ultrasonic energy, which passes through the material or, conversely, returns after reflection from an interface.

The ultrasonic test is focused on the detection of surface defects such as cracks, cold joints and duplication, the determination of wall thickness and larger individual volume defects in the material. Defects to the base material and welded joints are also detected and evaluated during testing.

BASIC STANDARDS USED

ČSN EN ISO 11666 NDT Ultrasonic test - Degrees of acceptabilityUltrasonic tests are performed by a UT inspector, qualified according to ISO 9712, level 2:ČSN EN 12223 Non-destructive testing - Ultrasonic testingČSN EN ISO 17640 NDT of welds - Ultrasonic testing of welded jointsČSN EN ISO 11666 NDT of welds - Ultrasonic testing of welded joints - Degrees of acceptanceČSN EN ISO 23279 NDT of welds - Ultrasonic testing - Assessment of the nature of indications in weldsČSN EN 10228-3 Non-destructive testing of steel forgings

* Evaluation of ultrasonic test according to the type of test and the above standards (e.g. ISO 11666).* We perform ultrasonic tests in our own and directly at customers’ premises.* A report on the inspections conducted is prepared according to the customer's criteria.