Welding reinforcing steel

According to EN ISO 17660 - 1 and 2

The execution of reinforcing steel reinforcements is governed by national laws, product standards and related regulations. For concrete structures, reinforcement is mainly used, which transmits tensile stress. The quality of the reinforcing steels is influenced by the production processes and the specific shape of the profile. Reinforcing steel bars are produced using a number of production processes and usually have a ribbed profile. Based on this, it is clear that a specific level of skill and working knowledge is required for the welder and the welding supervisor.

System and qualification requirements

Quality system:

Materials:The manufacturing company must have an established quality system in accordance with EN ISO 3834-3: Standard quality requirements for welding.

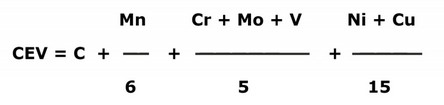

Only weldable reinforcing and stainless steel according to the relevant standards or technical specifications may be used. For the renovation and superstructure of buildings, the weldability of the existing reinforcing steel must be verified. Other types of steel may be welded to reinforcing steel. The delivery conditions of the steel must be stated in the Inspection Certificate.For reinforcing and structural steels, the CEV carbon equivalent value must be according to the product standard and calculated according to the formula:

Welding staff:

The manufacturer of welded joints made of reinforcing steels must have at its disposal a sufficient number of qualified and qualified technical and production workers according to ČSN EN ISO 17660 - 1 and 2, namely:* Welding supervision according to ISO 14731 with extension for reinforcing steels.* Welders with the test according to ČSN EN ISO 9606-1, extended according to TP A 217-Tests of welders - welding of reinforcing steels.* Personnel for NDT control according to ČSN EN 9712, EN ISO 17637.

Preliminary welding procedure:

The basic criterion for the manufacturer's ability to weld reinforcing steel is to meet the following qualification conditions:* Approved WPS welding procedures according to ČSN EN ISO 15609-1,2 and 5.* Prior to factory welding, all procedures must be qualified by the WPQR test for each welding method.

Production tests of welds:

This is conducted to ensure that under the specific conditions of the company for all welders and all WPQR, the same quality of the welded joint can be achieved according to the qualification of the welding procedure.

Production diary:

Each manufacturer must keep records of the production surveillance, known as the production logbook, showing the WPQR used, the results of all production tests and all relevant production data. The diary must be available at the workplace.

Further important information:

I. Frequency and conditions of production tests (VZ):

II: Evaluation of tests:* Production test – performed by all welders in the most difficult position.* Production test – performed in production every three months.* Production test – on assembly: always at the beginning of an order and then every month.* The test specimens must be welded to the appropriate WPS welding procedure specification and visually inspected prior to testing.* Samples must comply with grade "C" according to ČSN EN ISO 5817 (for arc welding methods) during visual inspection.

* Mechanical tests are performed according to ČSN EN ISO 15630-1 and 2.* The test results are recorded in the "Results Report".* If one sample fails, two more must be welded. If one of these samples fails, the whole welding test is deemed unsatisfactory.* If the production test of the welds is unsatisfactory, the welder must be trained before repeating the test.* Only after successful production tests of welds have been carried out can welding work be started.* Production tests of welds must be recorded in the "Production log" and archived for 5 years.